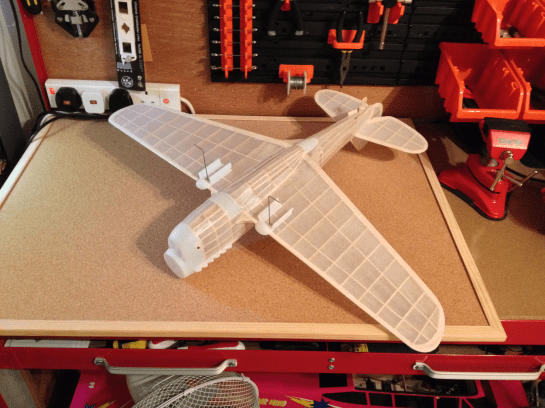

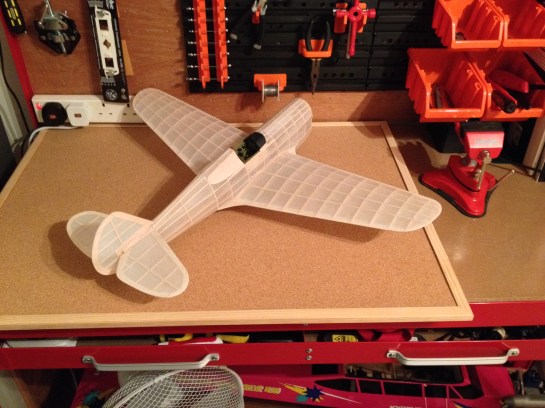

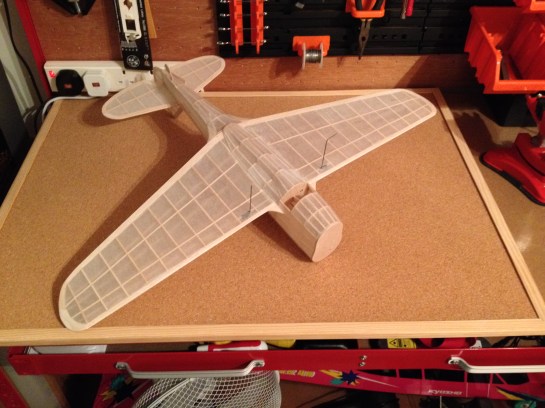

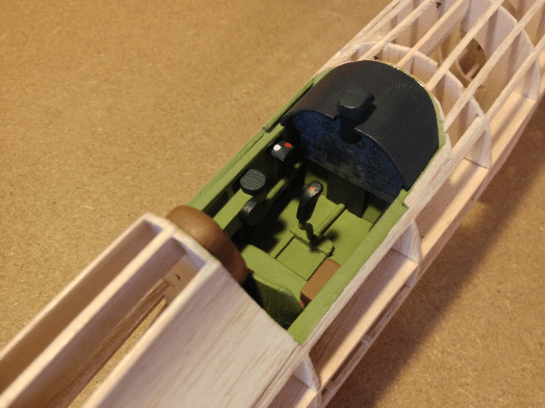

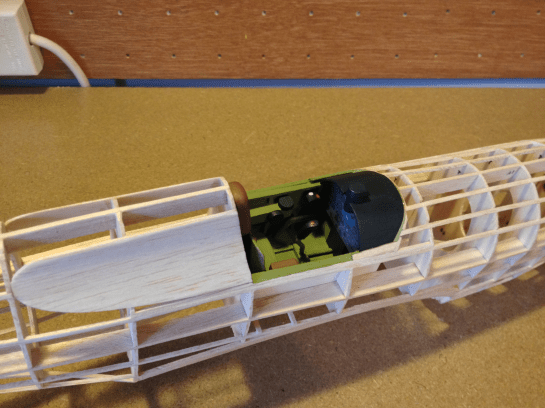

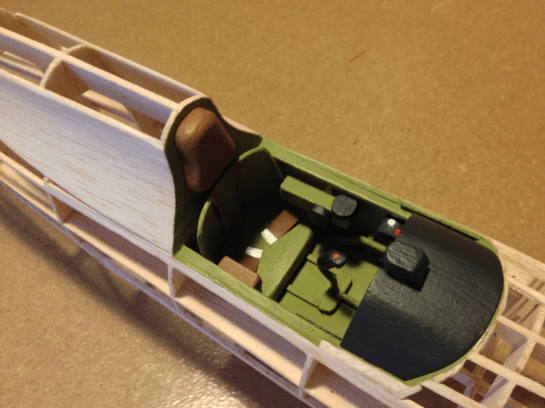

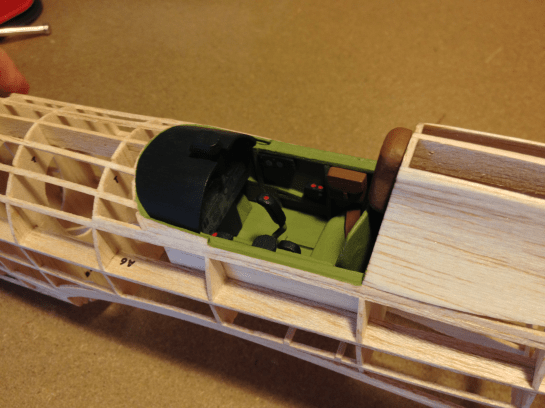

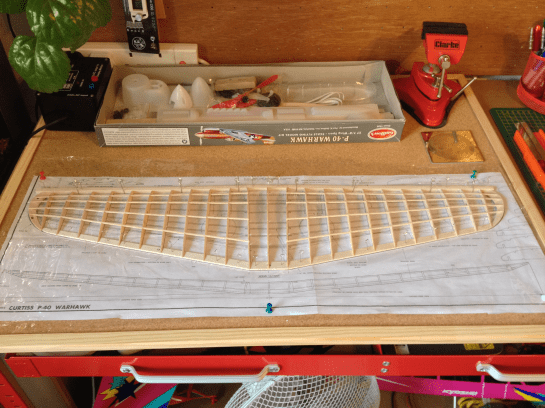

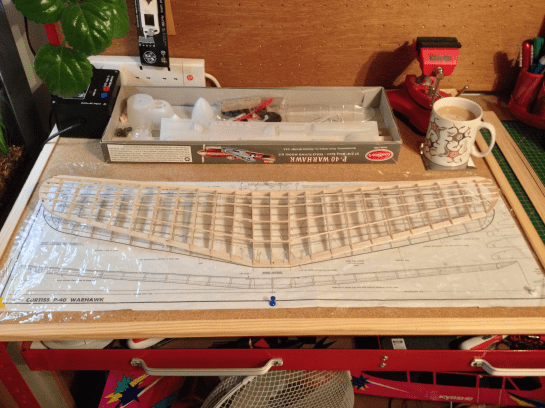

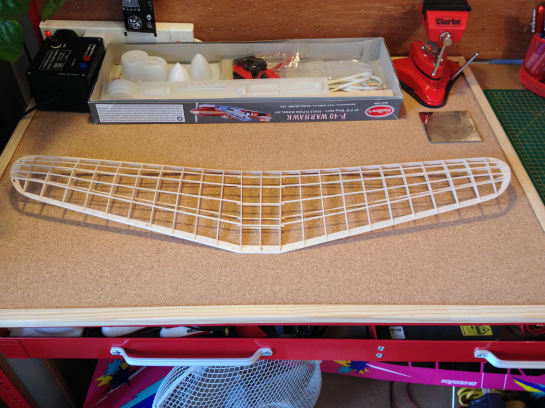

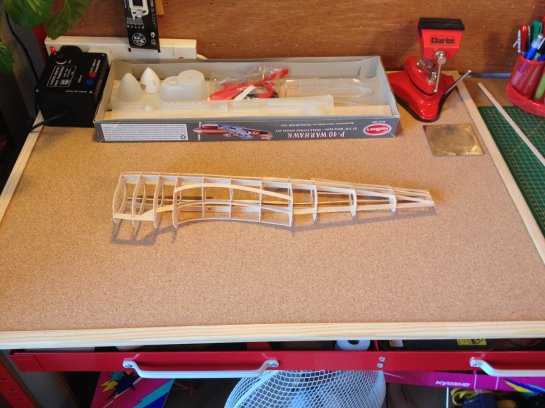

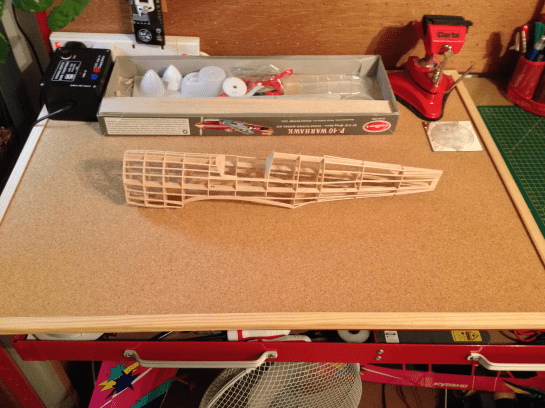

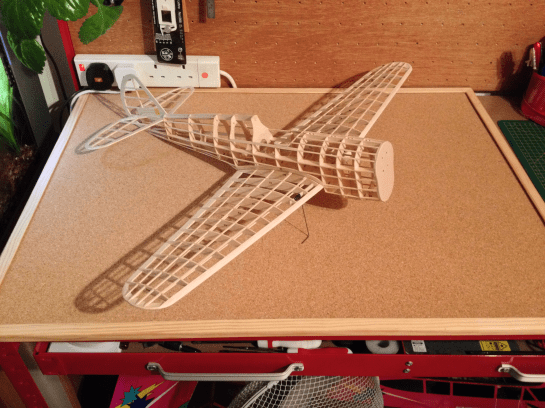

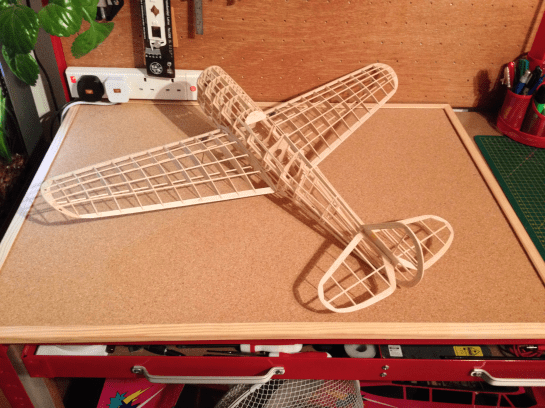

Guillow’s Series 400 P40 Warhawk Build:

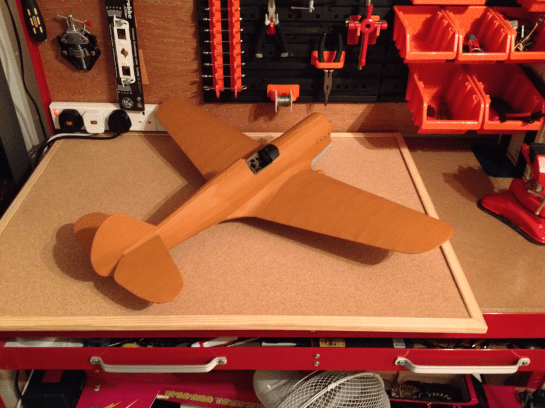

Paint:

If you have read my previous posts you may remember me drawing reference to the slightly ‘elastic’ feel of the Deluxe Material’s ‘Eze-Dope’ once dried. Thankfully the paint has stiffened the tissue covering up considerably. Following a spray with white primer the main colours were applied by brush. I prefer acrylics (Revell Aqua Color); after all what’s not to like with an odourless, water-thinnable paint which cleans up under the tap afterwards? Several coats were needed, as is to be expected from brushing, plus I don’t like the transparent look interspersed with brush strokes when the model is held up to the light.

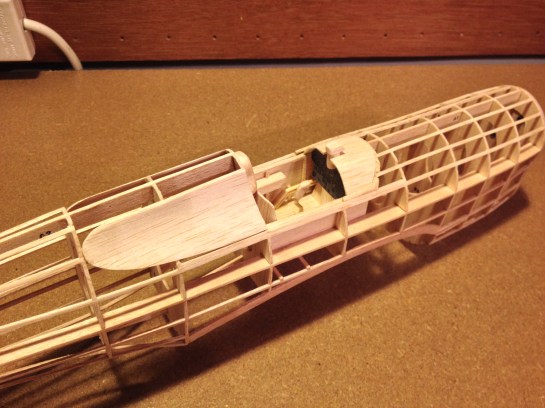

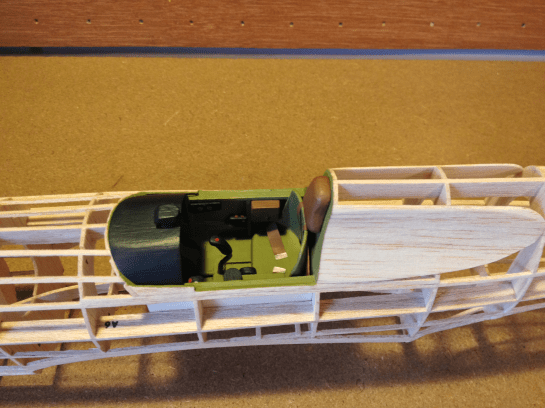

Painting any model, especially in more than one colour, is going to incur a weight penalty. The weight is now 152 grams including the cockpit detailing and undercarriage. A Cox Pee Wee .020 (0.33 cc) engine weighs 26 grams so I’m on track for staying under my maximum target weight of 200 grams. This engine is not exactly a power house when compared with a similar sized electric motor, but neither does it have to lug around a battery. For free flight this is good – landings are not going to be smooth and no battery equals no internal damage in the event of a sudden stop!