(I’ve uploaded the full set of MFA sport 500 manuals, templates, advertisements and magazine reviews here)

Finished and ready to go: This time with a healthy dose of mechanical sympathy!

Mechanical sympathy was a term coined by Jackie Stewart during his time as a Formula 1 driver. It was his opinion that the best drivers were those who also best understood the machines they drove. I learnt a lot about how my model helicopters worked and how best to handle tools and materials from my luckless battle with an MFA Sport 500. Now before I go any further I want to point out that there wasn’t anything wrong with the Sport 500. It was actually well engineered and designed specifically for the job of teaching its owner to fly. Unfortunately I feel MFA had perhaps forgotten the definition of ‘kitchen top engineering’ and what it is like to be a beginner with no idea how to accomplish the ‘simple’ tasks. For example the instructions did not explain how to tighten the prop nut on an engine that rotates in the same direction when there is nothing to grip onto!

To successfully build and fly the kit as designed really required a number of specialist tools that the average beginner just wouldn’t own. Without these most (me included) would try and substitute tools to get the job done. The result was to scratch, mangle, mash and strip the fragile aluminium and plastic parts and produce a machine that would soon vibrate itself apart before leaving the ground. All too often air did eventually appear under the skids of these poor helicopters; but unfortunately the lift wasn’t provided by the engine as it soared from the pilots outstretched hands into the trash.

On a strict school boy budget I was just about able to purchase the helicopter and radio. Tools however were another matter. My father wasn’t (and still isn’t!) good at DIY and had few tools in the garage. Construction of my Sport 500 therefore took place with nothing more than a junior hacksaw, a set of mole-grips, an old drill and a small assortment of ill-fitting screwdrivers. One weekend during my first GCSE year my technology teacher asked me to bring my ‘project’ into school and work on it as part of the school open day. I jumped at the chance as it would mean I would have access to all the high quality tools the well kitted out technology department had on offer. I did more towards getting my heli working in those few short hours than all the previous months of frustration and learned a valuable lesson that day; the right tools are required for the right job.

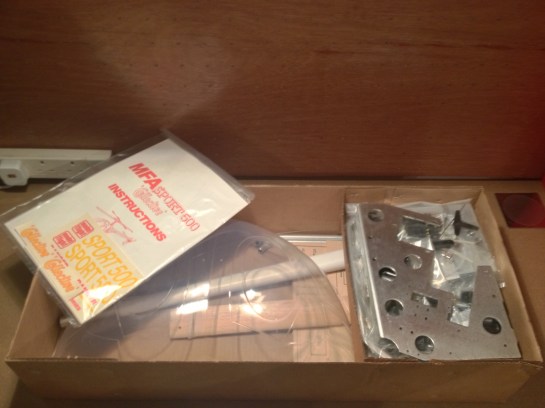

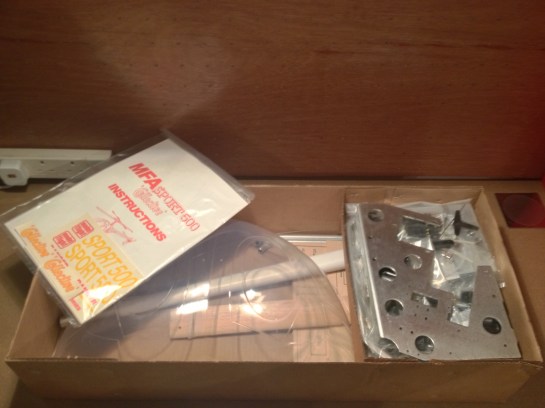

Today, 17 years later I’ve amassed a nice collection of hobby related tools and felt like I would like another crack at the Sport 500. I alluded to the purchase of this ‘new’ helicopter on eBay in a previous post. Quite a find in my opinion as it was an unbuilt boxed example. I also managed to track down a period correct Quest gyro and an unused series 1 SC40A engine. Construction went smoothly and the only modification I’ve made is to fit a third canopy mounting bracket to the underside of former F1 using a triangular cross section of ply to offset for the angle of F1. This should stop the canopy rocking back and forth in flight. Finally it wouldn’t look right with a 35MHz aerial extending back to the fin.

An enclosed price list dated 1990 confirmed my kit to be 23 years old. Miraculously though it still had that ‘new-kit’ smell.

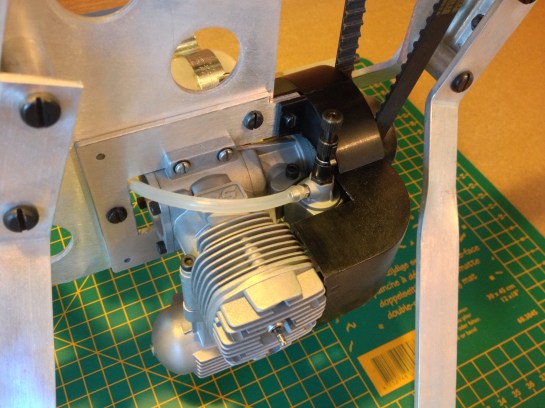

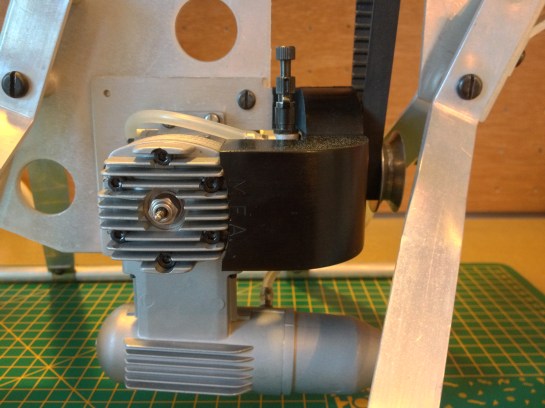

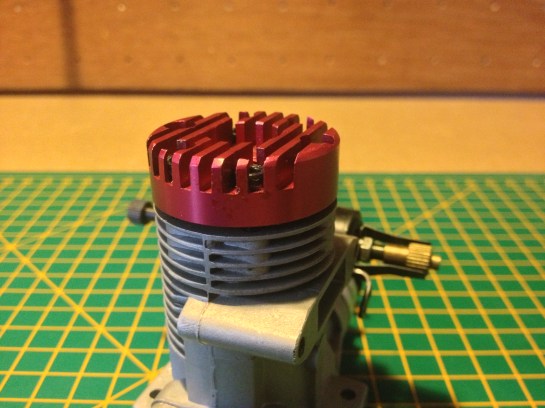

Main chassis assembled. Fitted is my favorite brand of engine for display models, a period correct, new in box, Series 1 SC40A.

Woodwork cut out and protected with fuel proofer and sanded between coats until a thick glossy surface was achieved.

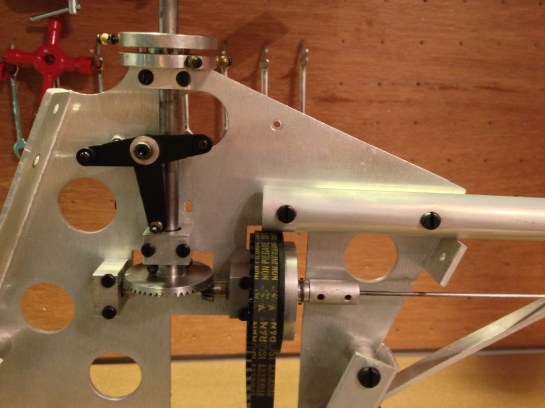

Radio tray complete with a vintage but fully functioning Quest gyro. (I’ve no idea how this will work in practice and might leave it in for ‘display’ and hide a miniature heading hold gyro behind it)

Canopy halves trimmed, joined and prepped for spraying

All painted with windows/doors outlined in trim tape.

Mechanics Left

Radio installation with receiver box and Quest gyro.

Dummy 35 Mhz aerial is a must for a machine of this age!